Wedge Wire Screen

Wedge Wire Filter

Wedge Wire Screen

Wedge Wire Screen is widely used throughout the world for water, oil & gas wells, and is the dominant screen type used in the water well industry.

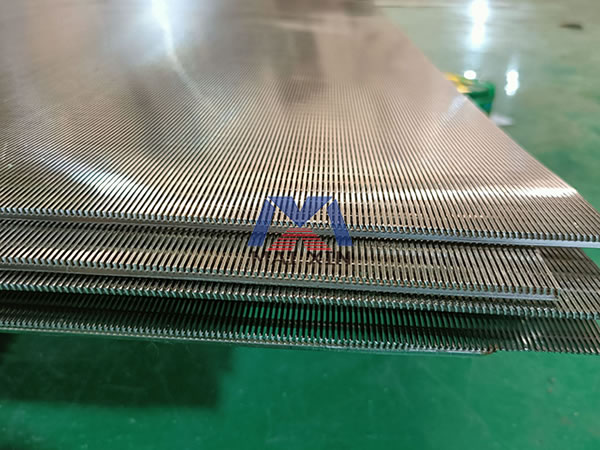

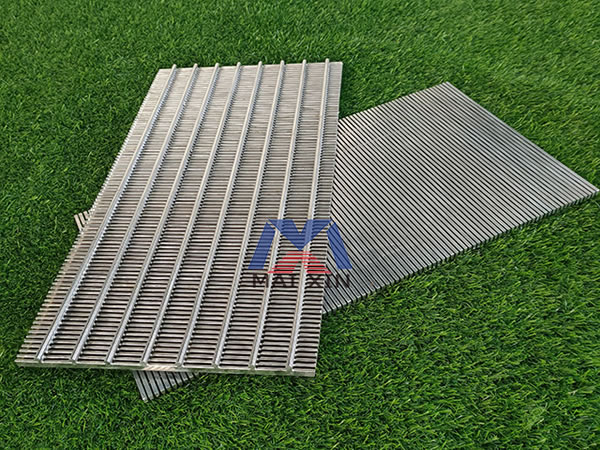

The welded stainless steel wire wrap screen is made up of rods and profile wire. The rod can be round wire, triangular wire or trapezoid wire. The profile wire is triangular wire (V-shaped wire). This type of wedge wire screen has a structure and high open area, as well as accurate slot dimension. The wire is attached to the rods by welding, producing rigid one-piece units having high strength characteristics at minimum weights. Slot opening for screens are manufactured by spacing successive turns of the outer wire to produce the desired slot size. All slots should be clean and free of burrs and cuttings. Each slot opening between adjacent wires is V-shaped, from the special shape of wire used to form the screen surface. The V-shaped openings designed to be non-clogging, narrowest at the outer face and widen inwardly.

| Standard Specification Data Sheet | |||||||||||||||

| Material | Slots (mm) | Outline Dimension (mm) | Accessories | Water Flow Rate | |||||||||||

| Width | Length | ||||||||||||||

| SS304, 316, 316L, 321, 904L, 2205 etc. | 10μm-5000μm | 100-2000mm | 100-6000mm | Frame or no frame, can be made on request | no clogging, high filtration accuracy, high capacity,easy to clean, durable structure, low pressure drops. | ||||||||||

| Usages | sewage treatment, food, starch, sugar factories, mineral processing, pulp and paper, textile factory, etc | ||||||||||||||

| Wedge wire | Width | 0.8mm | 1.2mm | 1.5mm | 1.8mm | 2.5mm | 3.2mm | 3.3mm | 4mm | ||||||

| Height | 1.9mm | 2.8mm | 2.5mm | 4.7mm | 4.3mm | 5.1mm | 8mm | 6mm | |||||||

| Relief Angle | 2.5° | 5° | 7.5° | 10° | 12° | 13° | 8° | 7° | |||||||

| Support rod | Width | /1.8mm | 1.8mm | 1.8mm | 2.3mm | 2.3mm | 3mm | 3mm | 4mm | ||||||

| Height | 12mm | 19mm | 25.4mm | 4mm | 3 mm | 7mm | 6mm | 8mm | |||||||

| OD | 4mm – 20mm | ||||||||||||||

Special specifications can be customized production.

Wedge Wire Screen

Wedge Wire Screen

Wedge Wire Screen

Wedge Wire Screen